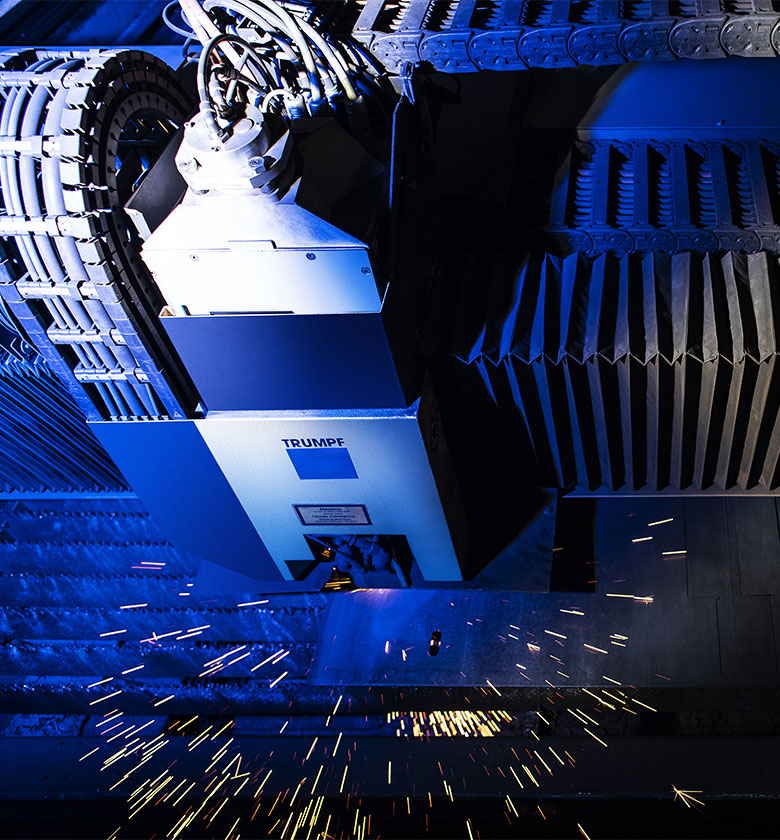

Plasma cutting

Plasma cutting, together with laser cutting, is a sophisticated processing technique that uses a plasma torch for cutting materials such as steel. Marchino, after several years of experience in the field, mastered this technique to perfection. Our company is equipped with a plasma cutting machine that has a work bench of 2.5x10m and a power of 260 A. This important availability has been created to offer our customers the best high definition plasma cutting with maximum thickness up to 30mm.

The plasma cutting was born around 1955 in the United States immediately after Robert Gage registered the patent for the Union Carbide, a multinational chemical company. Gage's idea was to develop a nozzle that would force the plasma to assume a rigid, firm and thin jet that cut the metal with extreme precision. In Italy, this technique came only in the 80s and quickly spread in the field of construction, industrial and mechanical carpentry thanks to a high processing speed and decidedly low costs.

All the advantages of plasma cutting

- adaptability (perfect for all conductive electricity materials)

- rapidity of cutting

- precision

- possibility to cut very thin plates or even those of considerable thickness