Laser cutting

Laser cutting is a widely used technique for sheet metal working, production of mechanical and building carpentry products, creation of metal projects for design and metal structures for the urban area. Marchino is the metal carpentry company specializing in this particular type of cutting for over fifty years, especially in laser cutting aluminum, iron and stainless steel sheets.

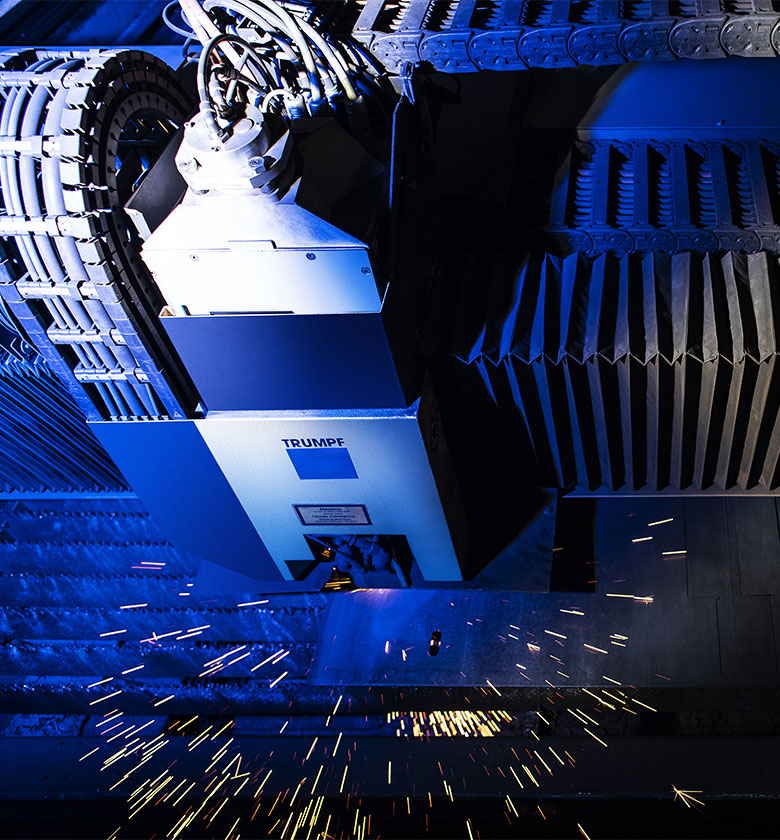

This is a highly sophisticated, precise, clean and smudge-free processing technique. Our company, to carry out any of your projects, is equipped with a laser cutting machine that has a 2x4m workbench set up with an automated loading and unloading system to offer our customers precise, clean and high definition cuts. Our instrumentation is able to achieve high standards of precision in metal sheets laser cutting available up to 25mm for iron and up to 20mm for stainless steel.

All the metal laser engraving advantages

Thanks to its powerful beam of light, the laser, through computerized control, melts the material and from an idea you immediately go to the action:- creation of even very complex metal structures

- production of objects with an innovative design

- the cutting material is kept clean thanks to the absence of direct contact

- speed

- extreme precision

- perfect shapes on your specific design

- high quality surface finish

- laser cutting is applicable on aluminum and steel