Since 1960 Marchino works

in the carpentry and metalworking sector.

Our company deals with working different materials

from aluminum to worked steel.

We work with structural steel, high strength steel strenx

or even wear-resistant steel, stainless steel and Corten.

In addition, we perform various processes including: laser cutting, plasma cutting, sheet calendering and bending, MIG MAG ELECTRODE and TIG welding of large and small carpentry dimensions.

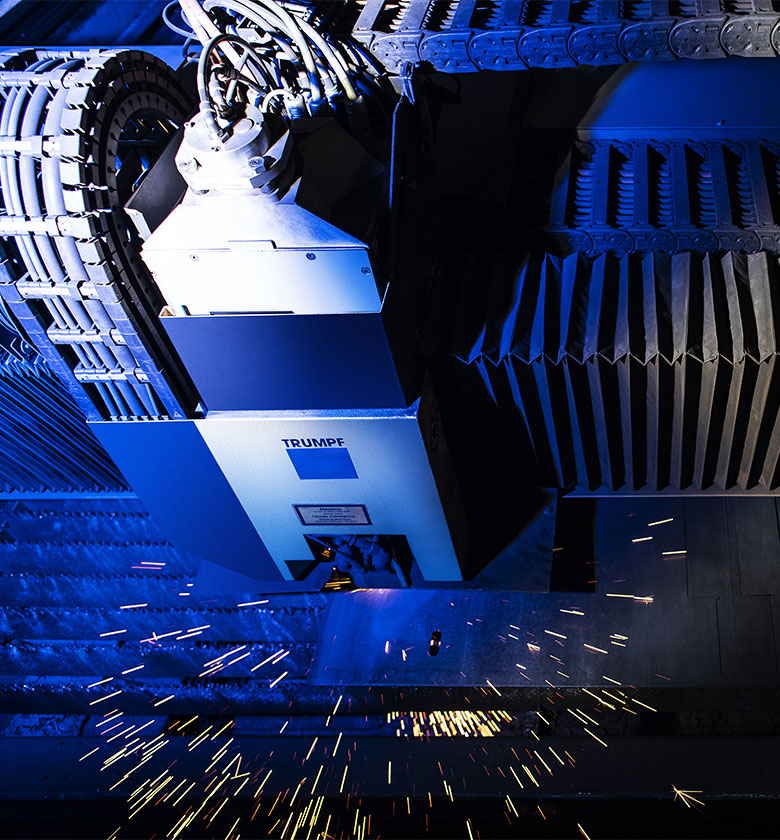

Laser cut

Thanks to a laser cutting machine equipped with a 2x4m workbench set up with an automated loading and unloading system to offer our customers precise, clean, high definition cuts. Sheet metal laser cutting available up to 25mm for iron and up to 20mm for stainless steel.Plasma Cutting

Our plasma cutting machine is equipped with a 2.5x10m workbench and a power of 260 A. This asset offers our customers the best high-definition plasma cutting with maximum thickness up to 30mm.

Sheet Bending

We have 4 bending machines with powers ranging from 130 to 1000 tons with a working range up to 10m.Sheet metal calendaring

In our company we have 2 4-roll calendaring systems for a maximum width of 3m up to a thickness of 15mm.

Welding

We have a positioner for welding with a capacity of 1500 kilogram. 15 wire welders with various capacities (MIG / MAG / ELECTRODE / TIG).Welding types:

Welding Full PenetrationSeal Weldings

Laser welding

Aluminum welding

All weldings are performed by carpenters equipped with a license emitted by the R.I.N.A.

Carpentry

We design and realise heavy and light carpentry manufacturing. Our production can meet the needs of different industrial sectors and civil construction.